The Australian construction industry is valued at AUD 161 billion now. Civil engineering and construction services are brewing at an exceptional rate here. Starting from the giant skyscrapers of Melbourne to the finest mining operations in the Outback, the construction sector is reaching new heights.

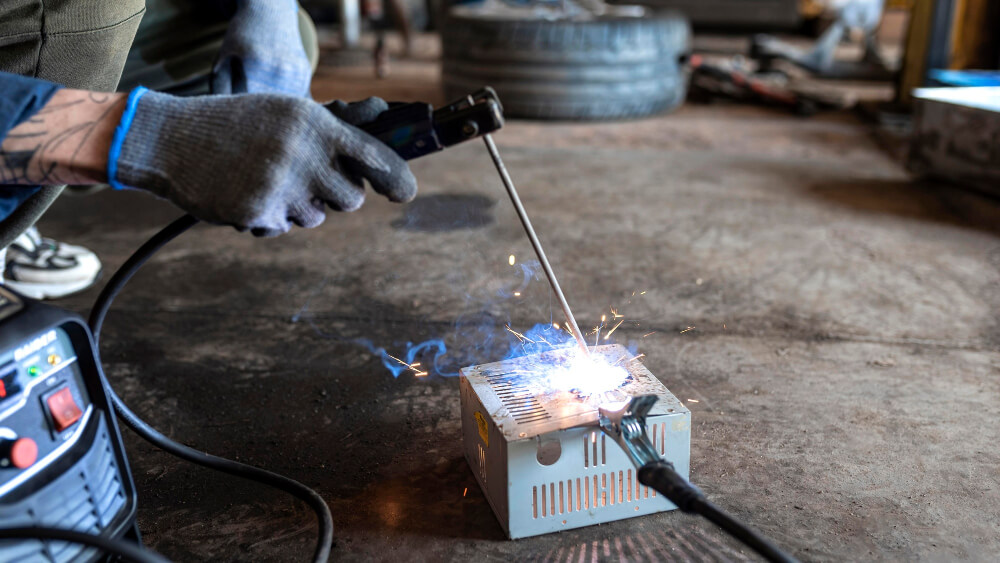

Therefore, the thing that we need the most is onsite welding. It is one of the most effective construction practices. It will also help the sector to grow leaps and bounds in the future.

This crucial component is however flexible and you can adopt it as per your project needs. Firstly seek the kind of onsite welding practices you need to finish your project on time.

We at Sutton Steel have extensive experience with onsite welding and fabrication. With this experience comes an understanding that onsite welding comes with its own set of challenges. However, these challenges are often overcome by adhering to the best practices and standards of onsite welding.

Application of Onsite Welding in Construction

Onsite welding is no rocket science. It is the hands-on welding work that welders do on the project side. But why is onsite welding a crucial component of every construction? Firstly it ensures seamless conglomeration of the project structure.

Secondly, it gives integrity to the asymmetrical and nongeometric structures which are very popular nowadays. Meanwhile, it is not only a process required for the mentioned structures. Any structure needs welding for its core framework to stand erect. At the same time site welding is essential for structural integrity.

You won’t find any construction work where onsite welding is not used in manufacturing the pillars of the construction site. But that is only the basic component of onset welding.

Structural steel fabrication

Not only brickwork. We need onsite welding for steel structures as well. Steel structures need onsite welding to a greater extent. It might be commercial buildings mining facilities or industrial facilities. To ensure the best assembly of the structure, there is nothing better than onsite welding. The process makes the assembly quick and efficient.

Pipelines and transport infrastructure

Thinking of large pipelines? The structure will be incomplete without onsite welding. It might be a water passage or an oil and gas pipe. It can also be your sewage system. None of the structures are complete without online welding.

The interconnected pipes ensure that the internal content passes through a leakproof pathway. At the same time, welding is important to expand and stretch the structure in any direction and shape it in the desired way.

It might be large and complex. However, transporting the pre-assembled components and onsite welding them is the easiest process.

Repair and modifications

Machine breakdown and equipment malfunction during construction is a daily matter. However, skilled on-site welders can bring a change here. They can easily repair the broken parts.

Therefore, you can ensure as a project manager that the project work never stops. Onsite welding is there for the best possible backup possible. If you want your issues fixed and your project up and running in no time, rely on good onsite welding practices.

Benefits of Onsite Welding

In the fast-paced and labor-intensive world of construction and industrial projects, onsite welding offers a range of benefits that make it the superior choice when compared with traditional offsite welding. These include:

- Convenience—it eliminates the excessive costs and logistics associated with transporting prefabricated components.

- Customization—allows components to be tailored to the specific requirements of the project.

- Immediate Corrections—Since the welding team is onsite, immediate corrective actions can be taken to prevent unnecessary delays.

- Cost-effective—On-site welding will prove more cost-effective in the long run, especially in large-scale projects.

- Quality Control—With the welders present throughout the process, the quality of the final product is ensured. This is especially important in tasks such as structural steel installation in Melbourne.

Challenges Faced During Onsite Welding

While onsite welding is extremely beneficial, it also comes with several challenges that would need to be properly addressed for the project’s safety and efficiency. Some of the challenges that can impact onsite welding include:

- Unpredictable Weather: Conditions such as intense heat and strong winds, such as those commonly seen in Australia, can impact weld quality with uneven cooling and contaminations.

- Limited Environmental Control: Unlike in a workshop where the conditions are optimal, you do not have the luxury of controlling the environment, which can lead to exposure and defects.

- Equipment Portability and Power Supply Issues: Transporting heavy equipment and ensuring a stable power supply can be tricky in especially remote areas.

- Worksite Safety Hazards: Fire hazards, exposure to harmful fumes, and working at heights, awkward positions, and confined spaces involve onsite welders having to take significant risks.

Safety Measures & Best Practices of On-Site Welding

Onsite welding has a range of risks. All project managers and welders must be aware of these risks. At the same time, you must know who is vulnerable due to these risks.

The construction sector facing the most risk is the structural steel fabrication sector. Onsite welding in this sector of Melbourne should be tactfully handled. You have to adopt the most remarkable industry practices to avoid risk. Firstly resort to genuine safety guidelines. Therefore you can ensure that welders are safe and they work flawlessly. Secondly, you can also ensure the project is finished in record time.

The common safety measures that every onsite welding project needs to follow, are:

1. Conducting daily or weekly site inspections to seek potential hazards before and after onsite welding operations

2. Ensuring welders have the necessary training and work as a team, therefore meeting the Australian welding standards

3. All welders on every onsite welding location should have personal protective equipment. The most essential equipment are helmets, fireproof clothing, and abundant respiratory support in case of emergency.

4. It is important to remove flammable materials from the main welding region and keep all fire extinguishers close by. The Australian welding standards also suggest that fire-resistant blankets can be of great help. Therefore you must have a few blankets near your welding site.

5. You must work in a properly ventilated area. It will help you to prevent the collection of obnoxious ferrous fumes

6. After that, you must secure all the power supplies connecting the welding area

7. Often welders work externally on lofty ceilings or unfinished floors. The Australian welding standards require all welders working in such locations to wear harnesses. He replies for any project where people work from heights or in confined spaces.

Final awareness

Onsite welding is a critical component of any construction sector. The emerging construction sector in Australia can’t exist without it. It has substantial benefits. Firstly onsite welding is flexible and saves cost. Secondly, it is a more efficient process.

Thirdly it has a range of challenges which can be mitigated. The bottom line is ensuring that the finished product meets the standard. You can also successfully navigate the challenges by following the best practices as per industry marks. On that note, you have to conduct a risk assessment and wear personal protective equipment.

Sutron Steel is one of the most prominent names in the Australian labor-intensive steelworks sector. You can rely on them for unmatched benefits. Currently, the demand across the Australian steelworks sector is brewing sharply. But, you need the best in town to work on your project!