Computerized Numerical Control (CNC) technology is expected to play an essential role in humanity’s future in the not-too-distant future. CNC bending machines, widely used in various metal industries, are already well-known for their effectiveness. Even though manual labor and mass assembly are still widely used, this technology rapidly displaces other production methods.

CNC bending machine, which uses a mechanical brake to create sheet metal, fabricated sheet metal. CNC bending machine breaks are available in various shapes and sizes, depending on the type of sheet metal being bent. Obtaining the most appropriate kind of CNC bending machine will increase the productivity of a press brake.

Understanding Your Organizational Preferences For CNC

While there are many different types of CNC wire bending machines available on the market, it may be beneficial for businesses to purchase one only after thoroughly assessing their current requirements and capabilities.

Extensive manufacturing facilities requiring symmetrical bending during the manufacturing process will almost certainly require a more advanced machine model. On the other hand, a simple DIY CNC bending machine may be sufficient to meet their needs for the most basic of functions.

A significant consideration in your purchase decision should be the volume of mass customization your company may require, with the higher the volume of needed mass customization resulting in a more advanced machine being required.

Professionals In The Field Of Operation

The operators’ skills have a significant impact on the quality of the output produced by this machine. CNC Bending machines are controlled primarily by computer-aided design (CAD) and computer-aided manufacturing (CAM). Professionals should take advantage of a machine’s full capabilities to the extent that the machines allow it to happen.

However, bending metals into long, symmetrical, and complex shapes may necessitate the use of sophisticated machinery, for which the technician or the end-user may also require specialized knowledge and experience. Technicians should also receive additional training on operating a modern CNC bending machine at the advanced level if necessary.

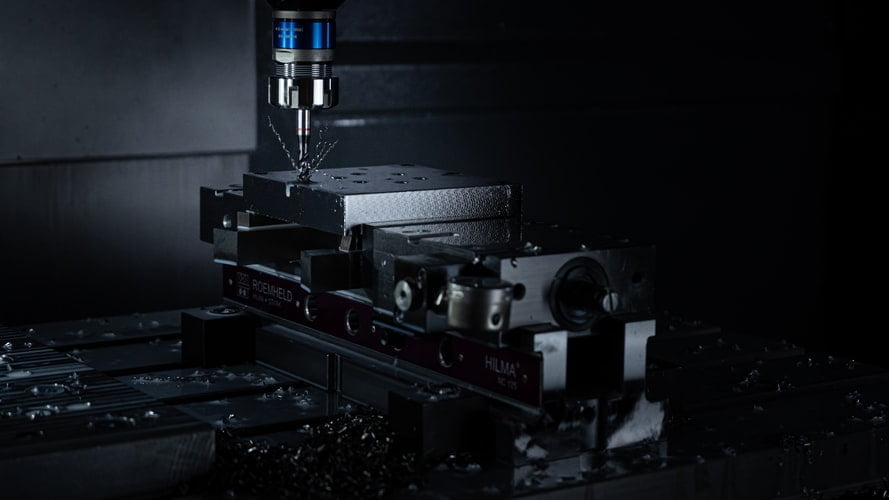

The Bending Process In The field

Tensile and compressive stresses are frequently encountered in the process of bending because of the residual stresses left behind after the CNC bending machine bending process. The sheet metal springs back towards its original position. For the sheet metal to achieve the desired bend angle, it must be overbent slightly. The amount of spring back is determined by the material used and the forming performed on it.

While sheet metal stays bent, the length of the sheet metal is increased. The bend result is some amount of stretch that this sheet metal shall experience when it is curved. Generally, this is calculated from the outside edges of the bend. The bend radius is defined as the radius of the bend on the inside. The bend radius that is formed is determined by the dies used, the material properties, and the thickness of the material.

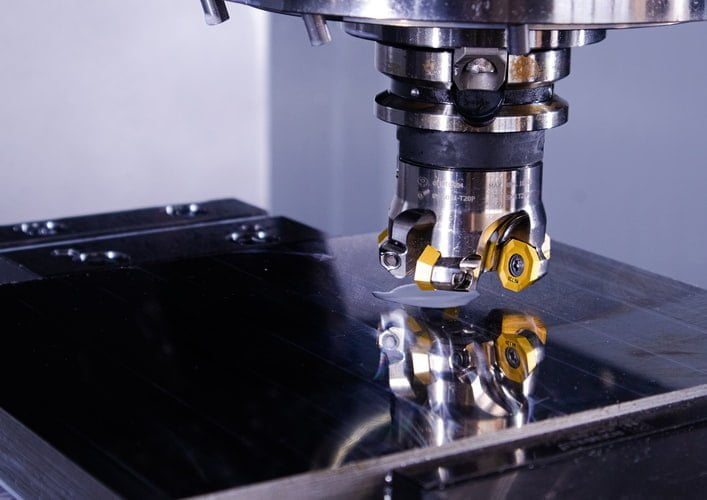

The Brakes Of CNC Bending Machine

In a CNC bending machine, there are four different types of brakes. A cornice brake, a box, pan brake, a bar folder, and a press brake are such devices. Even though the press brake is the most complicated tool, it is also the most effective. It bends the workpiece by clamping it between a punch and a die that has been designed to work together.

Wilson Tool is the best brand to use in a CNC bending machine when using a press brake. Their precision, performance, and innovation are at the cutting edge of the industry. As a result, producers can compete with the best fabricators in the world. This tooling has an innovative Nitrex high endurance surface enhancement that increases the tooling’s life by several times compared to tooling that has not been treated.

The Type Of Metals That Are Used For Bending

Using flexible metals or alloys may be necessary to achieve the desired output, while other products may require more rigid materials depending on the application. As opposed to springs or artisan products, which need flexibility, kitchen items or medical kits may require more rigid materials to achieve the desired rigidity.

As a result, while most machines are capable of working with a wide range of alloys depending on the type of shape required, some machines’ flexibility capabilities may be limited compared to others. It may be necessary to use a more advanced multiple arm CNC wire CNC bending machine to perform more flexible work or more complicated designs that require handling longer lengths of wire. The fact that companies produce various variants of the engine is a result of these specific requirements.

Conclusion:

It is expected to overtake them as the wave of mass customization sweeps the nation shortly. Customers can choose from various options to get the right equipment for their businesses, ranging from DIY CNC Bending Machines to larger bending machines and everything in between. And the CNC bending machines are the ultimate choice for industrial use.

Read Also: