In some industrial occupations, the movement of challenging loads – lifting, pulling, or locking – can be a familiar requirement. However, the manual element of this can present health and safety risks to the operator.

More and more, however, organizations are embracing technologies that can reduce these risks and maintain productivity. Jack screws are an example of this in action – a modern adaptation of growing technology that has been with us for years.

What Are Jack Screws?

Jack screws (sometimes known as jackscrews) are a form of, which is a device that delivers motion in a straight line. In comparison, the motion of most electric motors – for example – is circular.

Jack screws are quite straightforward in technical terms too. They consist of a screw affixed to their housing or machinery, which can then move in a set direction.

It’s important to remember that jack screws can come in various sizes too. Smaller sizes may be found in items such as household appliances. Larger sizes, meanwhile, can form part of an industrial or commercial system. Not only that, but you also get a choice of a ball or machine jackscrew. The main difference here is in the actual design of the screw itself.

How do jack screws work?

One other point to note when choosing a jackscrew is how it’s operated. In some applications, it might be operated by hand using a lever or handle to apply force to the screw.

But various jack screw options are driven by an alternate current or direct current motor. Again, the requirements for which one best suits you will depend on the application.

No matter what type of jackscrew is installed, the premise is very much the same. By turning the handle or applying electro-mechanical power, the screw moves to or fro – bearing its load in whichever motion is needed.

As a self-locking device, the screws remain in place and exert their force for as long as is required – or until they reach the end of their operational life.

What are jack screws used for?

Jack screws have multiple uses thanks to their varying sizes and forms. In electronics, screws are used in televisions and computers to fix D-type cable connectors in place. In this instance, they provide a reliable connection between devices and cables. But it’s also possible to find jack screws used in PCBs so that other components aren’t able to move.

In industrial settings, meanwhile, jack screws are used in heavy-duty applications. This could include the lifting and lowering vehicles in repair shops, for example.

Other applications of jack screws in the industry include aviation design and maintenance; medical equipment such as dentist’s chairs; theatre sets; and any other potential application where heavy loads feature.

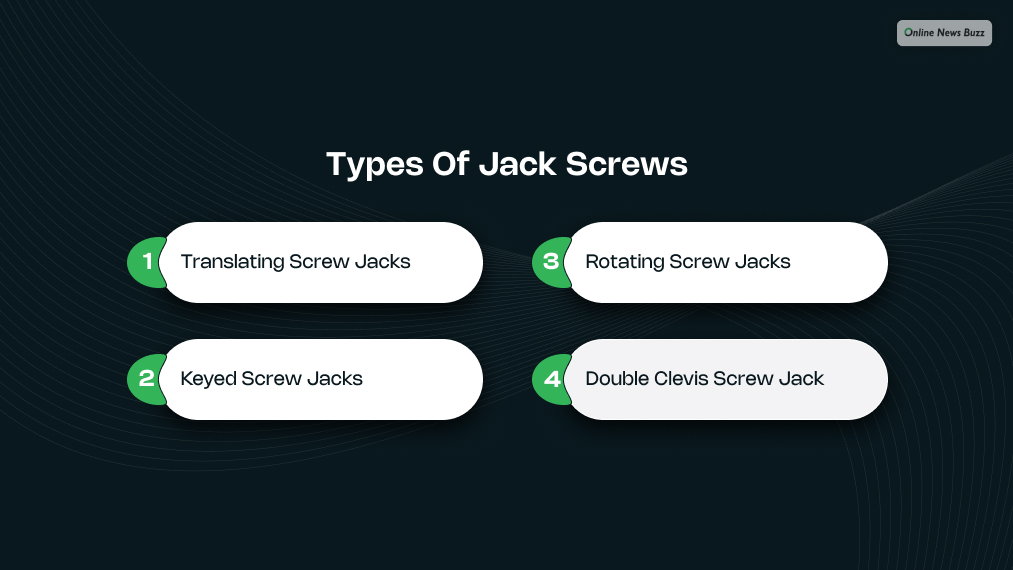

Types of Jack Screws

There are different types of screw jacks, and that includes machine screw jacks, worm gear, and ball screws. Their designs are different from one another, and their application and materials are also different. They offer versatile solutions for positioning and lifting. Here are the different types mentioned.

Translating screw jacks

This kind is one of the most common and can be used for various applications. The worm wheels rotate directly on the lead screw, making a linear movement. However, if the customer does not adjust the end of the lead screw, there is a chance that the lead screw will rotate because of the friction between the screw threads.

Keyed screw jacks

This one is a lot similar to the previous one. However, the lead screw is rotated to stop it from turning. It is important to connect the end of the lead screw to a load. Both non-encrypted and encrypted transmission screws have common applications where multiple jacks connect to one share load.

Rotating screw jacks

This setup fixes the lead screw to the worm wheel, making the worm wheel rotate, which drives the lead crew to rotate. This moves the nut with the lead screws as the nut is linked to the load.

Double clevis screw jack

These double clevis jacks are furnished at both ends with a clevis. One is mounted on the lifting screw end, and the other is welded to the bottom end of the cover pipe. They are typically used to move a load through an arc for angle title adjustments, like tracking hinged doors, air dampers, antennas, etc.

How will you choose the right screws?

To figure out what kind of jack screw is best for your work, you have to consider different factors like self-locking capabilities, load, travel speed or travel rate, duty cycle, price, accuracy, and efficiency.

- Work gear screws are good for multiple jack systems, as the torsional deflection of couplings and connecting shafts have very less effect on positioning. They are not designed for heavy-duty or high-use applications. They also have low efficiency and low travel rates. This lack of efficiency in worm gearing gives self-locking benefits.

- Beval gear ball screws have a 50% efficiency rate. This option provides flexibility for all forms of lowering, automated lifting, pulling, or pushing applications that need heavier-duty cycles and positional accuracy at high speeds. These are a little tricky to maintain. However, they are among the best choices for all kinds of work.

- Bevel gear jacks are best for moderate to light-duty cycle applications and cost a little more than worm gears because of their efficiency, speed characteristics, and flexibility. Even though they are a bit expensive, they have fewer components in multiple jack systems, which justifies the price difference.

The benefits of using jack screws:

In terms of the benefits of using jack screws, several stand-out factors work in their favor. The first is their consistency of application. Unlike a hydraulic jack that calls for a constant pressure of the fluid, jack screws can perform their task without ongoing force or power.

This is also related to their self-locking capabilities, which allow the jack screw to withstand the load without any force/power being exerted. It’s a big advantage when time or cost pressures mean ongoing monitoring or operation isn’t possible.

Jack screws are versatile too. This feature does a lot to explain why they prove such a popular solution. No matter what the challenge or application, these components can be fully relied on in situations as diverse as home electronics, commercial aviation, and industrial machinery.