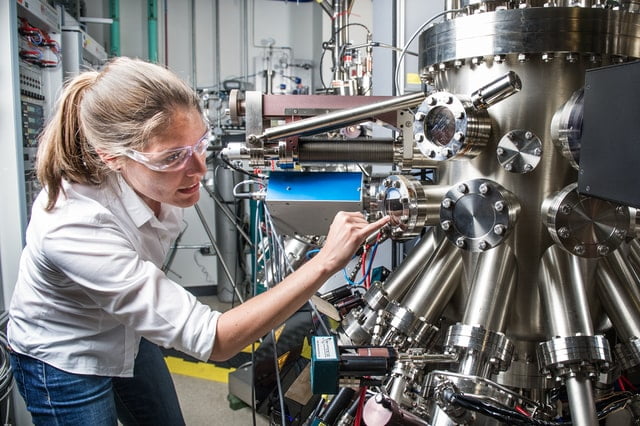

Adopting an excellent cleaning method is vital for every industry. Tools, devices, machines, and other apparatus used daily requires different levels of sanitation. In almost all industrial applications, ultrasonic cleaning is the most suitable method. It involves partially or fully submerging an object in a water-based solution to remove all contaminants through ultrasonic waves. In some cases, the addition of a cleaning agent or detergent may be necessary to meet cleaning standards.

Ultrasonic cleaning process described

The alternating negative and positive waves applied to the solution inside an industrial ultrasonic cleaner creates bubbles. These bubbles contain energy before released after the implosion. This implosion converts the bubble into small jets of energy capable of releasing and removing contaminants attached to the object. Moreover, the size of these bubbles and the pressure contained inside allows it to reach even the smallest crevices and corners.

Parts of an ultrasonic cleaner

Each ultrasonic cleaner consists of the following basic components:

- Radiating diaphragm

- Transducers

- Generator

- Cleaning tank

Currently, there are two types of transducers used in ultrasonic cleaners – magnetostrictive and piezoelectric. They have similar functions, but different performances and results.

For industrial applications, magnetostrictive transducers are preferred. These sensors are known for ruggedness and resistance to wear and tear. However, one downside is that it lacks efficiency compared to piezoelectric transducers.

Type of cleaning solution

The cleaning solution is a crucial consideration for industrial applications. In the past, the use of certain solvents was a standard. But as environmental laws became stricter in some countries, environment-friendly alternatives became essential. Ideally, you can use pure water as a cleaning solution. But when you do need to use a solvent or cleaner, always look for a solvent that is approved by industry standards and non-toxic. Mild detergent or soap is another cleaning agent used for ultrasonic cleaning.

Increasing the temperature of the cleaning solution also helps improve cleaning effectiveness. Generally, the higher the temperature, the better cleaning results. But the cleaning fluid shouldn’t be allowed to reach boiling point because it eliminates the pressure produced by the imploding bubbles.

Cleaning system design

Industrial ultrasonic cleaning equipment design should consider the required productivity rate, available space, and working environment. For heavy-duty applications, you’ll need to purchase cleaning equipment made of equally heavy-duty materials. The construction of the equipment will matter, especially when the machine runs frequently.

The degree of cleanliness required will also matter in choosing the design. Every industry follows different guidelines and a reputable supplier should be familiar with these guidelines and meet their customer’s needs by experimentation and trial runs.

Equipment retrofit and replacement

There are times when the more economical solution is to retrofit an existing cleaning system. For instance, you can opt to replace the transducers if you need to improve the machine’s performance. Your supplier should be able to recommend the best approach to retrofit an ultrasonic cleaner, or helping you find the right replacement if necessary. That’s why it’s vital to find a manufacturer that specializes in industrial-grade ultrasonic cleaning equipment, parts, accessories, and other service needs.

Read Also: