Cars have been around for over a hundred years, and during that time, the process of making them has drastically changed.

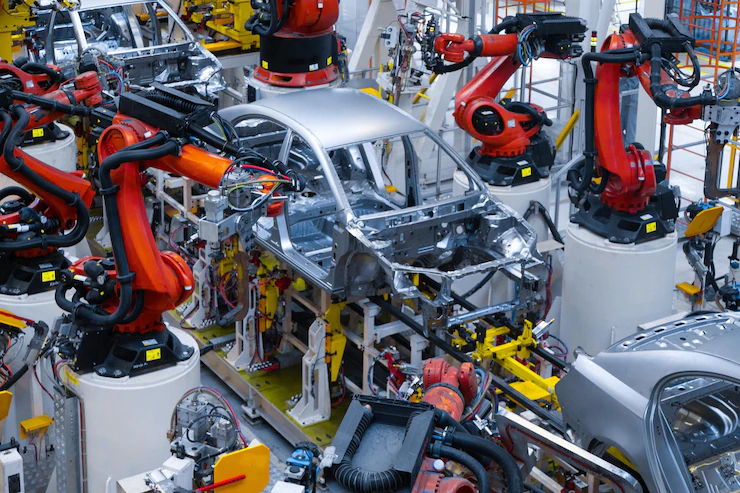

Many people think of robots as cold, metal creatures that can only be found in science fiction movies, but the truth is that they are integral to car production.

In this article, we will look at how robots are used in car manufacturing and the benefits they provide.

Types of robots used in car production

Robots come in various shapes and sizes and can be used to complete various tasks. Regarding car production, robots are generally used to replace human labor to increase efficiency and reduce costs. Three main types of robots are commonly found on the factory floor: articulated robot arms, SCARA robots, and delta robots.

Articulated robot arms are the most common type and are typically used to perform welding, cutting, painting, and assembly operations. These robots use joints to move in various directions and can be controlled by an operator or programmed with specific instructions.

SCARA (Selective Compliance Assembly Robot Arm) robots are specifically designed for assembly work; they use four axes of movement to place parts precisely into place with high accuracy.

Lastly, delta robots are 3-axis machines with a high speed of operation; they’re commonly used for palletizing and pick-and-place tasks due to their ability to reach different locations quickly.

Benefits of using robots in car production

One significant benefit of using robots in car production is the increased level of precision and accuracy they provide. Human operators may not be able to complete specific tasks as efficiently or accurately as a robot, so by automating these processes, factories can enjoy greater productivity and fewer mistakes.

Robots also offer cost savings; while they may require an initial investment in hardware and programming, they can save money in the long run due to their efficiency and low maintenance costs. Additionally, robots are much faster than human labor; this means more cars can be produced in a shorter time without sacrificing quality.

Lastly, using robots helps to ensure safety on the factory floor. Robot arms can move components around safely at high speeds, reducing the risk of accidents or injuries. Additionally, robots can take on dangerous tasks that may be hazardous to human operators, such as welding and painting, allowing people to focus on other tasks with less risk.

Disadvantages of using robots in car production

Although robots offer many benefits for car production, there are also some downsides.

As mentioned above, robots require an initial investment which can be expensive and difficult for some companies to afford. Additionally, programming and maintaining robots can be complicated; factories must hire experienced workers to handle these tasks.

A third possible disadvantage is that robots cannot always complete tasks as accurately or efficiently as human labor. Human operators often can think outside the box and find solutions that a robot cannot; this may lead to delays or errors in production if a robot cannot complete the task.

Lastly, it’s essential to remember that robots do not replace humans entirely. At the same time, they can take on specific tasks. Human operators still need to manage the robots and ensure everything runs smoothly.

Nevertheless, many companies have been working to mitigate the dangers and difficulties of working with robots. For example, Danish manufacturer Universal Robots has been producing cobots – collaborative robots – for many years.

The cobots they produce have a focus on working alongside humans instead of replacing them, helping human employees out with dangerous or repetitive tasks. Their affordable cobots are also easy to program and are highly adaptable, increasing flexibility in the workplace.

The future of robotics in car production

Robots are becoming a more critical part of modern car production, and this trend is expected to continue. Factories invest in sophisticated robots to complete complex tasks with increased accuracy and efficiency.

Additionally, new technologies such as artificial intelligence (AI) and machine learning will allow robots to become even more intelligent and versatile.

Conclusion

Robots are an invaluable tool for car production, allowing factories to enjoy greater precision and accuracy, and cost savings. In the future, robots will become even more advanced, taking on complex tasks with increased efficiency.

By investing in robots, companies can benefit from increased safety and productivity while reducing costs. While there are some downsides to consider, the advantages of using robots in car production far outweigh any potential drawbacks.

Additional: