As the name suggests the primary purpose of lifting shackles is for the lifting of heavy items, such as parts, products, and equipment. Here we provide an overview of lifting shackles, explain the different types available and also discuss the need for regular inspections.

Lifting Shackles an Overview:

At their most basic, lifting shackles can be used as tow ropes or for luggage, but at their most extreme lifting shackles can lift up to 150 tonnes, although manufacturer working load limits need to be checked very carefully.

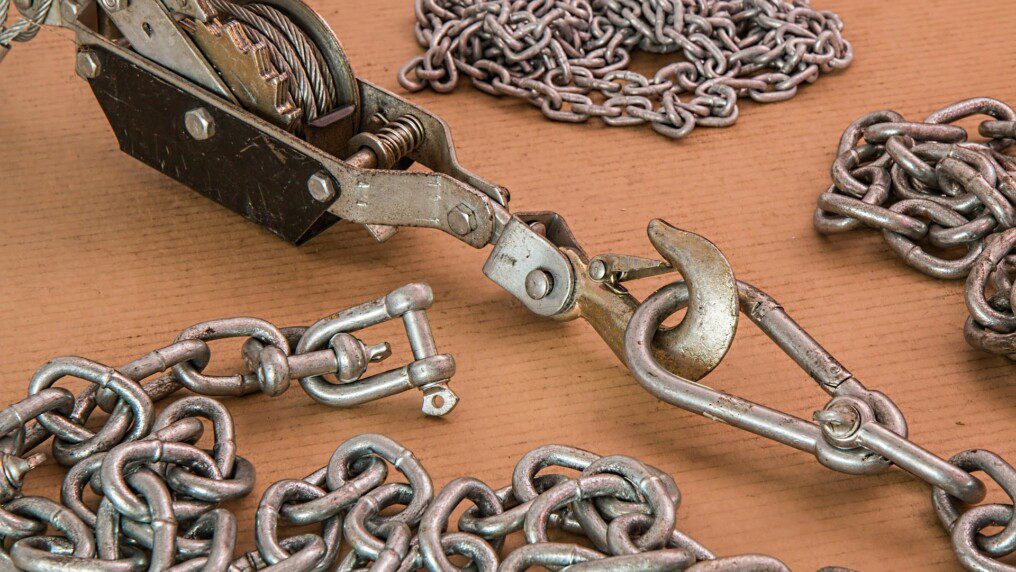

Shackles consist of two main parts, 1) the body and 2) the pin. The body is available in various shapes (which we cover below), examples are a bow, dee, snap and twist. The pin can be any of safety bolts (hex key), screw pins or split pins (clip design).

Shackles are designed for the durability and made from high-quality materials (usually steel). Although shackles are designed to work in extreme conditions it’s advisable to speak to the manufacturer if extremes of hot/cold are anticipated and/or where the environment is highly corrosive.

1. Bow shackles:

Bow shackles are also frequently known as anchor shackles. Bow shackles always have the familiar “O” shape appearance, which is not the look for any of the other shackle types.

The “O” section is perfect for the attachment of various slinging equipment, which could be any of chains, hooks, slings (web, round or wire). The “O” shape allows the shackle to take the weight from numerous directions and avoids side load.

The Bow Shackle overall though has less strength than other shackles due to the larger shape of the loop. So, this shackle should be used for smaller to medium weights only.

2. Dee shackles:

Dee shackles are also sometimes referred to as “D” or chain shackles. Dee shackles are narrower than bow shackles, have straight sides, are round shaped on end and have either a pin or threaded pin closure.

Dee shackles when loaded perpendicularly are able to lift much larger loads than a bow shackle equivalent, this is a benefit of the small loop. But a drawback of dee shackles is that they are not suited to angular loading, which may cause the shackle to bend or twist. The primary use of dee shackles is the lifting of heavyweights in a straight line.

The headboard shackle is often discussed, this really is just a longer version of a dee shackle and therefore doesn’t need to be listed as a separate shackle type.

3. Snap shackles:

Snap shackles are a type of shackle, which has a fast action spring-activated mechanism. They can be operated with one hand and are ideal for use where speed is all-important, or where connection/reconnection is likely to be a regular occurrence.

Snap shackles have much lower working load limits when compared to any of the other shackles and are therefore definitely not suited to heavy-duty applications but can be useful in some situations. If this shackle is used for heavy-duty loads the split ring or pin assembly is very likely to fail.

4. Twist shackles:

Twist shackles are longer than the other types of shackles. They feature a 90° twist (hence the name), this means that the top area of the loop is always perpendicular to the pin. This is a specialist shackle with fairly limited uses, the main application for twist shackles is in connecting gears in rigging operations in sailing.

5. Soft shackles:

Modern man-made synthetic fibers can be used to create super-strength ropes, which when tied into lockable loops are called “soft shackles” in the lifting industry. Soft shackles possess many advantages over metal-based alternatives:

- Are easier to undo

- Are much less noisy, with no rattling noises when not in use (e.g. wind-induced)

- Have less components, such as pins, so have less likelihood of breaking

- They hurt less if they hit staff – so suit confined environments

Inspection of lifting shackles

Lifting shackles like all lifting equipment should be inspected on a regular basis, here are some recommended checks:

- Pins/bolts should be checked for blemishes, distortion, fractures, and wear

- Pins/bolts which are bent should be immediately replaced

- Pins/bolts must be completely seated and in place

- The shackle body must be checked for bending and replaced if there is evidence of any bending

- Shackles which have excessive wear or have elongated pin holes or eyes need replacing

Read Also: