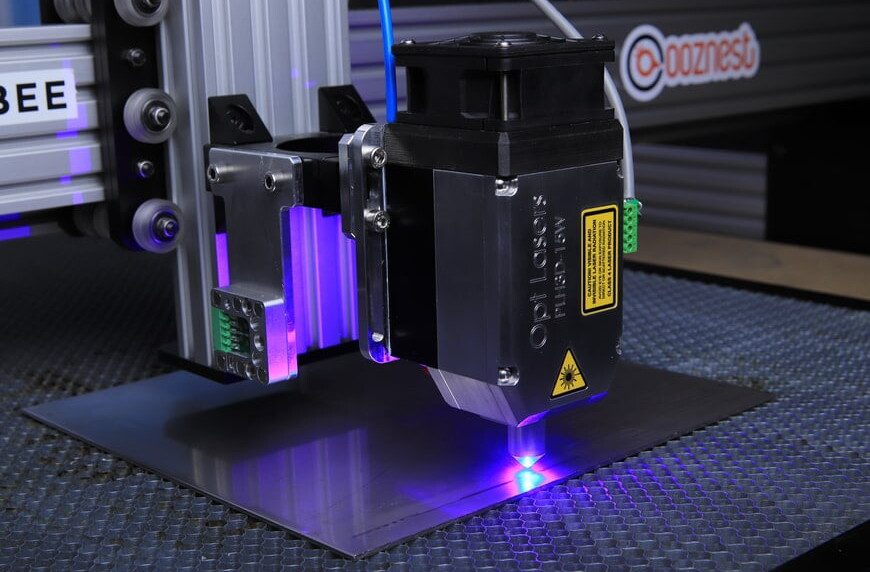

Laser cutting is a technology that is used in the process of fabrication. This instrument is used to cut flat-sheet metals in the manufacturing process. The metal laser cutter at Advanced Cutting Technology because of its ability to make precise cuts and unmatched speed.

There are plenty of excellent benefits of using this advanced technology. It provides you with quality and efficient work and helps you to save lots of time, effort, and money. Here are some of the most significant advantages of using this high-tech mechanism for manufacturing work:

4 Advantages Of Using The Metal Cutter

Metal cutting is heavy-loaded work, especially when you do not use the right tools for it. However, as time passed, the metal architects became more and more perfect about their works. And they want to use the best tool to enhance the perfection level of their work. The metal laser cutter is among these excellent metal cutting tools.

Are you searching for a precise metal cutter? Here are the four advantages of using the metal laser cutter for your projects.

1. Energy Usage

Due to the advanced level of technology used in the metal laser cutter consumes way less energy than several other cutting methods. This means that it not only provides you with efficiency but also helps you to save electricity.

While other cutting mechanisms might use the electrical energy of up to kilowatts, the laser cutter for metal sheets only consumes up to 10 kilowatts of power.

This also caters to the manufacturing team with the opportunity to work smart by using both less energy as well as environment-friendly technology.

This means that during the fabrication process, the metal laser cutter will help you save effort, cost, and energy in the most efficient manner.

2. Cutting Versatility

Another one of the essential advantages of using the laser cutting technique is that it can be used for a vast number of various tasks other than just cutting through metal materials.

You can certainly engrave, mark and drill with the help of laser technology without even getting into much hassle of replacing the tool. This means that laser cutting technology can certainly be used for almost every material.

From stainless steel to metals like copper and brass, and even the non-metals like textile, plastic, and wood can also be cut with the help of advanced technology of the laser cutter.

3. Precision Cutting With Perfection

When it comes to precision in the task, there is almost no comparison of the metal laser cutter due to its high level and advanced technology used in it. Small corners and small designs cutting are more time-consuming. But when you are using the metal laser cutter in seconds, you can complete your project with perfection.

These laser cutters are capable of cutting even the geometric shapes and edgy patterns with a high level of accuracy with the help of high degree CNC router programs. In addition, these cutters are used to create smooth finishing and clean edges.

For this very reason, it not only helps to reduce waste during the manufacturing process but also assists you in creating high-quality and adequate parts.

4. Improve Your Work Consistency

Because the laser cutters are programmed with the help of CAD/CAM software, it helps to create accurate parts and helps you to make sure that the same cuts can be used and repeated as many times and as possible.

Since a metal laser cutter can provide you with quality and precise results. It can help you ensure that the same shape and cuts can be used multiple times without any consistency issues.

This turns out to be quite helpful when you have to manufacture multiple products of the same quality size and shape with perfect accuracy levels.

Wrapping It Up:

A metal laser cutter is a brilliant tool. When you are using the tool you can save the heavy loaded work and achieve the perfection level. So when you want to improve your work efficiency and quality, innovative tools like the metal laser cutter are compulsory. Even the automatic laser cutting tools are run in the automatic mode based on scanning the design. So use the intelligent tools and complete your project with more perfection.

Read Also: