Of all the puzzles an electrical engineer has to solve, from complex circuitry to power distribution, you wouldn’t think labeling a cable would be a big head-scratcher.

But get it wrong, and that simple wire marker can become a source of frustration, confusion, or even a safety risk down the line.

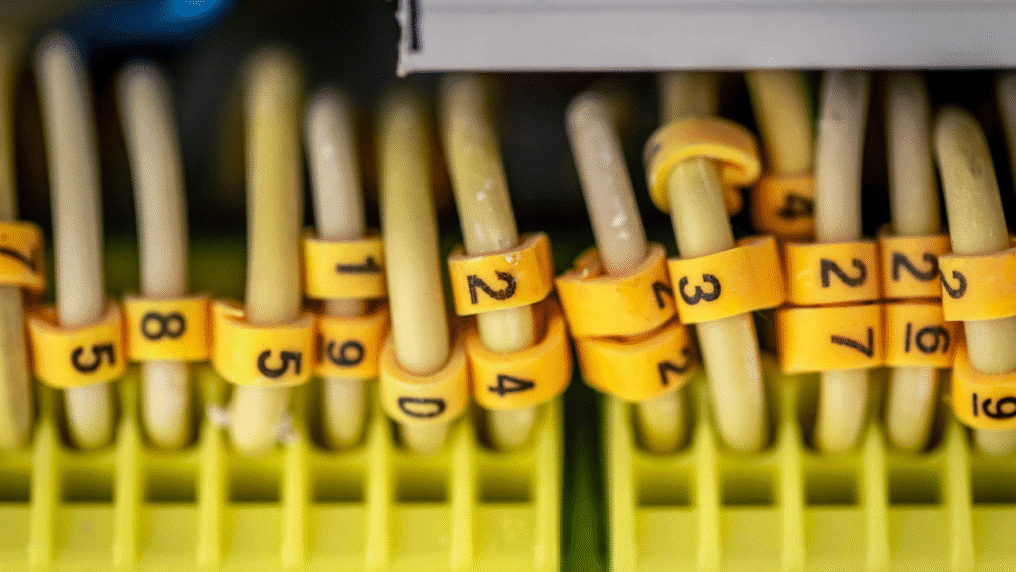

Choosing the right cable marking systems is like giving every wire its own clear, durable name tag.

It’s a small detail that makes a huge difference in organization and efficiency, So, let’s learn how to choose the right cable marking system.

How To Choose The Right Cable Marking System?

How does one choose the right cable marking system from the smorgasbord of options? Let’s break down the three heavyweights in the labeling ring: trusty manual labeling, sleek thermal transfer, and high-tech laser printing.

1. The Old Reliable: Manual Labeling

Imagine the classic garage workshop: functional, straightforward, and hands-on. That’s manual labeling in a nutshell.

We’re talking about writing on adhesive labels with a permanent marker or using pre-printed labels that you just peel and stick.

Best for: The DIY fix, small-batch projects, and on-the-spot changes. Additionally, you can also use this for environments where a simple, low-cost solution is all that’s needed.

Think home labs, small control panels, or making a quick note during troubleshooting.

Watch out for: Let’s be honest, handwriting can get… messy. It might be legible to you today, but will anyone else be able to decipher it in five years?

Durability is also a question, as ink can smudge or fade over time, especially if exposed to oils, chemicals, or just the friction of being handled. For large-scale or permanent installations, manual methods often aren’t robust enough.

2. The Middleweight Champion: Thermal Transfer Printing

If manual labeling is the handy workshop, thermal transfer printing is the efficient, professional print shop.

This method uses a handheld or desktop printer. This applies heat to a special ribbon, which then transfers a durable, smudge-proof image onto a self-laminating label.

The result? A crisp, professional-looking label that’s wrapped in a protective clear layer.

Best for: This is the go-to for most professional applications. If you need a batch of labels with consistent, legible text and barcodes that need to withstand a challenging environment, thermal transfer is your best buddy.

It’s perfect for control cabinets, factory floors, and data centers where labels might face exposure to moisture, light abrasion, or chemicals.

The real win: The self-laminating feature is a game-changer. It protects the printed information from wear and tear. Also, it ensures it stays readable for the long haul.

It is for everyday industrial use. It offers a fantastic balance of professional:

- Quality

- Durability

- Affordability

3. The High-Tech Heavyweight: Laser Printing

Enter the future of labeling: laser etching. This process doesn’t add any material to the cable or sleeve.

Instead, it uses a concentrated beam of light to permanently alter the surface material. Then, it vaporizes it to create a high-contrast mark.

So, it’s not printing on the cable. It’s becoming part of it.

Best for: The toughest jobs on the planet. If your cables are going to be dragged through oil, baked by the sun, sprayed with harsh chemicals, or abraded daily, laser marking is the ultimate solution.

It’s ubiquitous in extreme industries like aerospace, automotive manufacturing, offshore energy, and food and beverage processing, where indelible, permanent identification is non-negotiable.

Why it rules: The mark won’t peel, smudge, or fade because it’s literally etched into the material.

It’s incredibly resistant to heat, UV light, solvents, and abrasion. While it often requires a more significant initial investment, its permanence and durability are unmatched.

Picking Your Labeling Partner: A Quick Guide

Choosing the right system boils down to matching the method to the cable’s mission. Think about where it’s going to live its life.

● The Benign Indoor Cabinet

This is an easy life. We’re talking climate-controlled panels, server racks in clean rooms, or low-traffic data closets.

Here, threats like physical abrasion, chemicals, or weather are virtually zero. A well-written manual label can work for quick fixes.

But a basic thermal transfer label (even without heavy-duty lamination) will provide a clean, professional look that will last for years without any fuss.

It’s all about simplicity and cost-effectiveness for a comfortable environment.

● The Factory Floor (Oils, Coolants, Mild Abrasion)

This is the industrial workhorse environment. Cables here face a daily challenge. One of the biggest challenges is the occasional splashes from coolants.

Additionally, they can also come into contact with lubricating oils, dust, and light physical abrasion from workers or equipment brushing past.

This is the absolute sweet spot for thermal transfer printing. So, using a self-laminating label is the key.

The printer creates a crisp, legible mark, and the clear laminate layer seamlessly wraps over it, creating a protective barrier that shields the print from moisture, grime, and chemical splashes, ensuring long-term readability despite the rough-and-tumble setting.

● Extreme Conditions (UV, Chemicals, High Heat, Weather)

This is the ultimate endurance test. You have to picture outdoor applications under the blazing sun.

Then, you have to imagine these cables in chemical processing plants submerged in aggressive solvents, or those in automotive manufacturing facing constant high heat and abrasion.

In these scenarios, laser etching is the undisputed champion. The process doesn’t just sit on the surface.

It permanently alters the material’s outer layer, making the mark incredibly resistant to

- Fading from UV light

- Dissolving from harsh chemicals

- Wearing off from abrasion

- Melting under intense heat

So, you can safely say that the mark is designed to last for the entire life of the cable.

How Many Labels Do You Need? (The Volume Gauge)

- A Few: Manual is fast and cheap.

- Dozens or Hundreds: Thermal transfer printers excel at batch printing consistently perfect labels.

- Mass Production: Integrated laser marking systems can be automated for continuous cable marking.

Permanent or Temporary? (The Longevity Check)

- Temporary/Identification for Testing: Manual is fine.

- Permanent Installation: For most, thermal transfer is durable enough. For critical, life-of-the-equipment permanence, laser is the answer.

Choose The Right Cable Marking System Today!

At the end of the day, a wire marker is more than just a tag. It’s a critical piece of communication.

It tells a story to the next technician who comes along. Additionally, it ensures they can work safely and efficiently.

Also, you can opt for the simplicity of a hand-written label. You can also take advantage of the professional reliability of thermal transfer or the indestructible power of laser etching.

But, regardless of these choices, the right choice is the one that ensures your project’s story remains clear for years to come.

Read Also: